Prior to the past week or so the Panaracer Gravelking SS+ 700C x 43 had been rock solid. Compared with my prior two sets of WTB tubeless tires, one set of Ventures and one set of Byways, the Gravelking SS+ had held air like a champ and shown none of the problems of microholes that seemed to bedevil the WTB tires.

Notice that I said prior to the past week. I kind of want to take back all of the good words that I lavished on the Gravelking SS+.

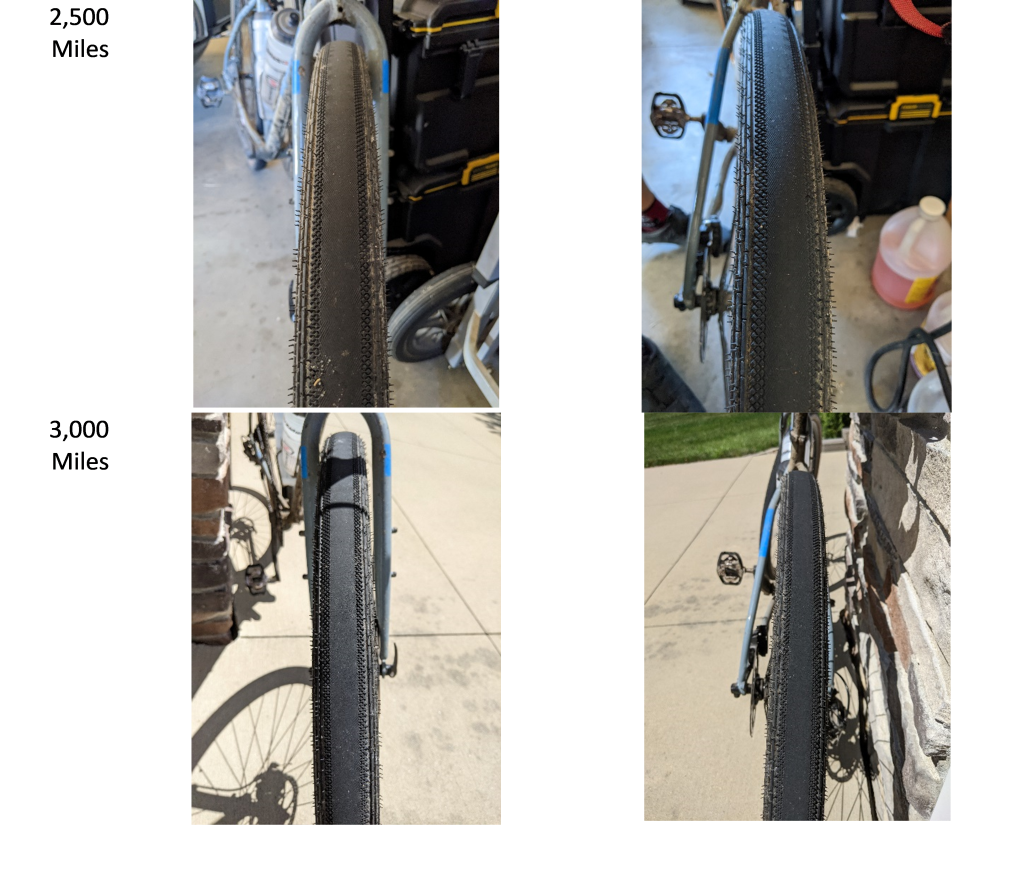

First, the rear tire on my Breezer started weeping sealant through the tread area like crazy:

This is just a taste of what it looked like every morning. I would have blamed the sealant, Orange Endurance in this case, but the front tire did not have any leakage. I would have blamed something on the trail poking holes in the tire, but again there was nothing damaged on the front tire.

Like a fool I poured some additional sealant, Orange Endurance again, and continued my early season riding. Everything seemed normal. The tire continued to have spots of sealant weeping. However, it was holding pressure on long rides (30+ miles) and overnight, so I chalked things up to the strange swings in temperature/humidity we have been having this spring. One day it is 65 degrees and the next it is 90 degrees with similar swings in the humidity.

Like I fool I went out for a ride this morning when less than three miles from my house the rear tire on my Breezer self-immolated. There was a sound like a balloon popping followed by a complete flat. I walked the half-mile or so to the trailside air pump hoping that a little air pressure might allow things to reseal since I saw no obvious major damage.

With a pump or two of air sealant was leaking out of the valve stem and spoke nipples:

Maybe I should have cut bait on these tires when the rear tire started weeping sealant. Maybe I should have rotated the tires and rebuilt the tubeless setup at the beginning of the season. Maybe I should have switched brands or type of sealant.

Thankfully I was close enough to home to call a ride to get my ruined bicycle back to the shop and in for some much-needed repairs. It’s enough to make a guy go back to using tubes.

Posted in bikes, Uncategorized

Tagged 2021, 40C, 700C, bicycle, Breezer, Byway, compressor, Enduro, gravel, Gravelking SS, Iowa, knobs, orange, Panaracer, ProTite, puncture, Radar, sealant, semi slick, tires, tread, tubeless, valve core, Venture, width, WTB